●The VST-9000-MHI Electric Utility vehicle includes the following components and functions.

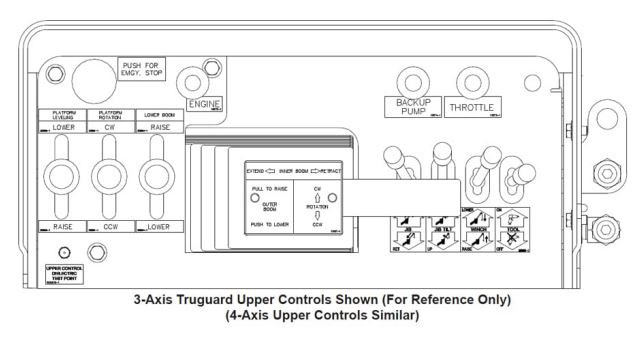

●Single handle control on the upper part of the working bucket(upper and lower boom lift, lower, turntable rotation), including safety trigger function and emergency stop/drain valve.

●Remote engine start/stop, upper and lower control, 24V.

●The bottom turntable rotates 360 degrees continuously in both directions.

●38L/min flow, open hydraulic system. Pressure: 205kg/cm².

|

|

|

|

Description

BRIEF

Bucket trucks serve a vital role across various industries, including local telecommunications and utilities, facilitating tasks like power line maintenance. These trucks come in diverse sizes and configurations, tailored to address electrocution risks inherent in tasks involving electrical infrastructure like wiring, cables, and poles. Their versatility significantly streamlines operations, enhancing efficiency and safety standards.

Primarily utilized by power linemen, bucket trucks enable them to execute their duties comfortably and securely. These professionals rely on such equipment, especially in environments featuring steel or concrete poles. The utilization of bucket trucks not only ensures the smooth execution of tasks but also minimizes potential hazards associated with working at heights and around live electrical components.

In essence, bucket trucks represent a cornerstone of modern utility and telecommunications operations, offering a safe and efficient means of accessing elevated workspaces and conducting maintenance tasks. Their prevalence underscores their indispensability in industries where worker safety and operational efficiency are paramount concerns. Whether it’s repairing power lines or conducting routine inspections, these specialized vehicles facilitate seamless workflow, contributing to the overall reliability and functionality of essential infrastructure networks.

FEATURES

The VST-9000-MHI Electric Utility vehicle boasts an array of components and functionalities, including:

● Convenient single-handle control located atop the working bucket, facilitating upper and lower boom lift, lower movement, and turntable rotation. Equipped with a safety trigger function and an emergency stop/drain valve.

● Remote engine start/stop and 24V upper and lower control capability.

● 360-degree continuous rotation of the bottom turntable in both directions.

● Open hydraulic system with a flow rate of 38 L/min and pressure up to 205kg/cm².

● Side-mounted telescopic upper boom enabling retraction of the working bucket at a low position.

● Upper FRP insulation boom measuring 3,000mm in length.

● Lower boom insulation section (chassis protection system)measuring 610mm.

● Inner surfaces of the insulating boom and section are coated with a wax compound to prevent moisture accumulation, while the outer surface features gel paint. The glass fiber-reinforced plastic resin contains an anti-ultraviolet inhibitor.

● The entire system employs non-lubricated bushings.

● Hydraulic tool interface integrated into the working bucket.

● Integral hydraulic oil tank with a capacity of 95 liters and 2 viewing windows.

● Fiberglass working bucket (with steps) designed for 2 individuals, measuring 610×1,220×1,070mm.

● Working bucket capable of 180º horizontal rotation and tipping.

● Fully insulated telescopic boom with a voltage withstand capability of ≥220KV.

● Master/slave hydraulic leveling function, including upper control dumping function for cleaning the work bucket and personnel rescue.

● Upper boom storage rack equipped with fixing straps and bucket support.

● Inclusive of all necessary hardware.

● Comes with 2 sets of operation and maintenance manuals in Chinese and English.

● Manual throttle control operating at 24V.

● Emergency hydraulic system operating at 24V DC.

● Manual hydraulic jib crane with a maximum load capacity of 454kg.

● Supplied with a set of spare air tubes painted white by TIME.

● Design safety factor of steel structure: ≥ 3 and insulation material: ≥ 8.

● Features 1 roof engineering emergency light.

● Includes 1 upper and one lower insulating arm cover.

● Comes with a pair of walkie-talkies.

● Supplementary items such as test strips, top arm cable, aluminum lining, corona ring, and microammeter are included.

Bucket Truck

90 ft Insulated Articulated/Telescopic Material Handler

Industries Served

Electric Power Distribution, Electric Power Transmission, Electric Utilities

Type

Articulated Telescopic, High Access

Height Range

65ft – 100ft

Model Series

HIGH ACCESS, VST

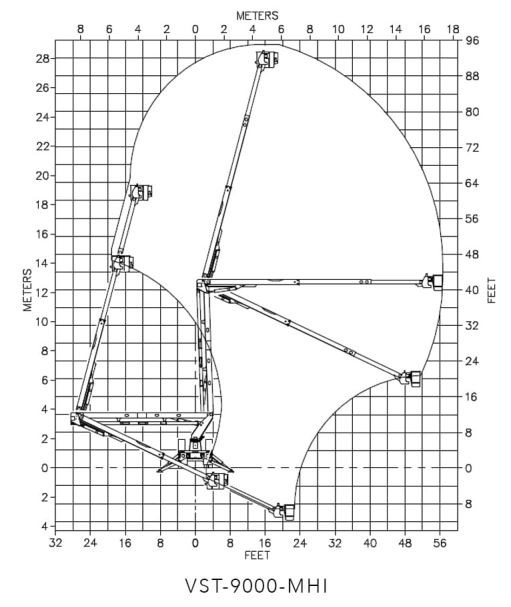

Working Chart

SPECIFICATIONS

|

BODY ASSEMBLY |

|

|

TYPE |

ARTICULATED TELESCOPIC, HIGH ACCESS |

|

MODEL |

VST-9000MHI |

|

MAKE |

VERSALIFT(USA) |

|

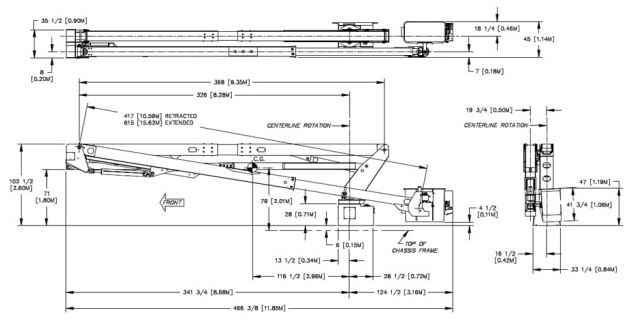

DIMENSION |

|

|

Overall length |

12,050mm |

|

Overall width |

2,490mm |

|

Overall height |

3,990 mm |

|

Wheelbase |

4,625+1,350mm |

|

Front track |

2,022mm |

|

Rear track |

1,830mm |

|

Front overhang |

1,500mm |

|

Rear overhang |

2,900mm |

|

WEIGHT |

|

|

GVW |

25,000kg |

|

TARE WEIGHT |

11,050kg |

|

Axle load distribution |

7,000/18,000kg (tandem axle) |

|

PERFORMANCE |

|

|

Working Height |

30m |

|

Height to Bottom of Platform |

28.3m |

|

Horizontal Reach |

17.07 m |

|

Stowed Travel Height |

3.66 m |

|

Platform Capacity |

317.51 kg |

|

Insulated or Non-insulated |

Insulated |

|

Material Handling |

Yes |

|

Working Voltage |

10-220kV |

|

Working Temperature |

-40 ºC – 45 ºC |

|

Humidity |

≤95% |

|

Workable at an Air velocity |

6-level wind speed |

|

Platform Lifting Time |

67s |

|

Platform Lifting Speed |

0.22m/s |

|

Platform Dropping Time |

51s |

|

Platform Dropping Speed |

0.3m/s |

|

HYDRAULIC SYSTEM |

|

|

Hydraulic Controls |

Full Hydraulic |

|

Operating Pressure |

3000 psi (210.92 kg/cm²) |

|

Flow Rate |

10 gpm (37.85 lpm) |

|

Filtration |

10 micron return | 100 mesh suction |

|

System Type |

Open Center |

|

Power Source |

PTO Pump |

|

BOOM |

|

|

Inner/Outer Boom Articulation |

-25º – 85º |

|

Lower Boom Articulation |

0º – 88º |

|

Inner Boom Extension |

198 in (5.03 m) |

|

Insulated Boom Length |

3m |

|

CHASSIS TRUCK |

|

|

TYPE |

6×4 Drive |

|

MODEL |

HOWO 340 |

|

MAKE |

SINOTRUK |

|

PERFORMANCE |

|

|

Min. Ground Clearance |

258mm |

|

Max.Gradeability |

28.5% |

|

Approaching Angle |

32 º |

|

Departure Angle |

13 º |

|

Min. Turning Radius |

22m |

|

Max. Speed |

95km/h |

|

ENGINE |

|

|

Make |

SINOTRUK |

|

Model |

D10.34-40 |

|

Type |

4 stroke, 6 Cylinders, intercooler, Turbocharged diesel engine |

|

Emission Standard |

EURO 4 |

|

Power |

249kW (340hp) @ 2500rpm |

|

Max Torque |

-960N.m@1500rpm |

|

Displacement |

9.7L |

|

STEERING |

|

|

Model |

ZF8098 |

|

Type |

hydraulic steering with power assistance |

|

Drive Position |

Left Hand drive |

|

TRANSMISSION |

|

|

Model |

HW13710, Manual |

|

Gear Numbers |

10 forward&2 reverse |

|

PTO |

HW70 |

|

TYRE |

|

|

Size |

295/80R22.5 |

|

Numbers |

11 pieces(1 spare) |

|

ELECTRICAL |

|

|

Battery |

2X12V/165Ah |

|

Alternator |

28V-1500kw |

|

Starter |

7.5Kw/24V |

|

CAB |

|

|

Model |

HW76 |

|

Type |

Sleeper Cab |

|

Equipment |

AC, heating |

|

Capacity |

3 including driver |

|

Color |

Yellow |

CSCTRUCK INSTALLATION

– Mounting auxiliary beams, power take-offs, and hydraulic pumps;

– Attaching VST-9000 MHI bucket body imported from Mitsubishi Heavy Industries onto a SINOTRUK chassis truck.

– Fitting H-shaped outriggers;

– Installing the outrigger control valve;

– Adding toolboxes on both sides;

– Employing imported anti-rust materials and processes for painting the chassis and toolboxes;

– Conducting insulation tests by the China Electric Power Research Institute according to national standards before leaving the factory, with certificates issued and tests subject to purchaser supervision.

ON-BOARD SPARE PARTS AND TOOLS

1) Working bucket cover, insulating arm cover

2) 1 spare tire

3) 2 seat belts

4) 4 outrigger pads

5) A set of inch tools (1 set each for opening/plum blossom and inner hexagon)

6) A set of Isuzu on-board tools