Make & Model: CSCTRUCK / GC14BJ270R3

Drive Type: 4×2 Left Hand Drive

Wheelbase: 4,600mm

Chassis Designed: FOTON AUMAN

Loading capacity: 14m³

Engine Make / Model: WEICHAI/WP10.270E32

|

|

|

|

Description

BRIEF

The garbage compactor truck is specifically designed for efficient refuse collection, packing, transportation, and unloading, incorporating integrated combined operations. It features a compactor garbage tank system body mounted on the reliable FOTON AUMAN truck chassis. This system comprises several key components that work together seamlessly to streamline waste management processes.

Firstly, a sturdy subframe is connected to the truck chassis, providing a solid foundation for the entire garbage compactor system. This subframe ensures stability and durability during operation.

The heart of the system is the high-strength, wear-resistant steel plates welded tank. This robust tank is capable of withstanding the rigors of heavy-duty waste handling. It securely houses the garbage, preventing spillage or leakage during transportation.

To facilitate efficient garbage collection and compaction, the truck is equipped with a hopper composed of sliding plates, a sweep panel, and other relevant components. These elements work harmoniously to gather and compact the garbage effectively, optimizing the available space within the tank.

For convenient unloading, the truck features a hydraulically opening tailgate and a garbage bin tipper. These mechanisms ensure smooth and controlled discharge of the waste, minimizing manual effort and enhancing operational efficiency.

The garbage compactor truck options for operators. From the comfort of the cabin, operators can control the vehicle’s functions using the cab-in control system. Additionally, manual control and push button control options are available, sequentially enabling precise command execution. This sophisticated control system enables the truck to perform automatic cycle work, further enhancing productivity and reducing the need for extensive manual intervention.

In summary, the garbage compactor truck is a highly capable and efficient vehicle designed to streamline refuse collection, packing, transportation, and unloading operations. Its robust construction, integrated components, and advanced control system ensure seamless and automated waste management processes. With this innovative truck, waste management becomes more effective, contributing to cleaner and healthier communities.

FEATURES

1. Large Capacity: The Foton garbage compactor truck 14m³ is equipped with a spacious compactor body that allows for a large capacity of waste storage. With its 14m³ capacity, it offers ample space to handle a significant amount of garbage, making it suitable for high-volume waste collection and disposal tasks.

2. Efficient Compaction System: This garbage compactor truck is designed with an efficient compaction system that helps reduce the volume of waste. The truck’s compactor mechanism compresses the garbage, allowing for maximum utilization of the available space. This feature enables more efficient waste collection and transportation, minimizing the number of trips required to dispose of the garbage.

3. Advanced Hydraulic System: The FOTON Garbage Compactor Truck 14m³ incorporates an advanced hydraulic system to power its compactor mechanism. The hydraulic system ensures smooth and reliable operation, providing high compaction force to effectively compress the waste. It offers precise control over the compactor mechanism, enhancing the overall performance and efficiency of the truck.

4. Robust Construction: Built with durability in mind, the FOTON Garbage Compactor Truck 14m³ features a robust construction to withstand the rigors of waste collection operations. The truck’s body is made from high-quality materials that are resistant to corrosion, impact, and wear, ensuring a long service life even in challenging environments. This durability minimizes maintenance and repair costs, making it a cost-effective choice for waste management companies.

5. User-Friendly Design: The FOTON Garbage Compactor Truck 14m³ is designed with user convenience in mind. It features an ergonomic cabin layout with easy-to-reach controls and a comfortable seating arrangement for the driver. The truck also incorporates safety features such as rearview cameras and warning systems to enhance operational safety. Additionally, it has user-friendly controls for the compactor mechanism, enabling operators to handle waste collection tasks efficiently.

SPECIFICATION

|

PARTS |

ITEM |

DESCRIPTION |

|

1) General Information |

1.1 Make & Model |

CSCTRUCK / GC14BJ270R3 |

|

1.2 Date of Manufacturing |

Chassis EXT 2020 and body made in 2023 |

|

|

1.3 Country of Origin |

China |

|

|

1.4 Truck Unit’s Status |

Brand new |

|

|

1.5 CSCTRUCK’s Status |

Established and reputable |

|

|

1.6 Drive Type |

4×2 Left-Hand Drive |

|

|

1.7Overall Dimension (L x W x H) |

8,960×2,520×3,150mm |

|

|

1.8 Max. Gross Vehicle Weight |

18,000kg |

|

|

1.9 Curb Weight |

11,100kg |

|

|

1.10 F/R Axle-Load |

6.5/11.5T |

|

|

1.11 Wheelbase |

4,600mm |

|

|

1.12 Air Over Hydraulic System |

The chassis system is an air-over hydraulic |

|

|

1.13 Rear Tow/Pintail Hook |

Installed |

|

|

1.14 Standard Tool Kit |

Supplied |

|

|

1.15 Mud Flaps |

Installed |

|

|

1.16 Chassis Designed |

FOTON AUMAN |

|

|

1.17 Cabin |

Hydraulic power steering type. 1 driver+2 passengers |

|

|

1.18 Drive wheel(Tires ): |

4+2and one spare (total 7 wheels) |

|

|

1.19 Loading capacity: |

14m³ |

|

|

2) Engine

|

2.1 Make / Model |

WEICHAI / WP10.270E32 |

|

2.2 Country of Origin |

China |

|

|

2.4 Type |

6 cylinders in line, 4 strokes direct injection, water cooling, Intercooler Turbocharged |

|

|

2.5 Air Intake |

Turbo-charged |

|

|

2.6 Fuel |

Diesel |

|

|

2.7 Cooling System |

Water cooling system |

|

|

2.8 Displacement |

9.726L |

|

|

2.9 Nominal Power |

270HP (199kW) @ 2,200rpm |

|

|

2.10 Peak Torque |

1,100N.m@1,200~1,600rpm |

|

|

2.11 Emission Standard |

Euro 3 |

|

|

2.12 Max. Rotated Speed |

1,200~1,600rpm |

|

|

2.13 Bore x Stroke |

Φ126×130mm |

|

|

2.14 Used |

The engine is used to power the remaining system through a hydrostatic drive and all components through a hydrostatic drive. |

|

|

2.15 Electronics |

The engine electronics accept a remote variable throttle for stationary operation through transmission-mounted PTO and transfer case-driven PTO equipment. The air cleaner is to be the manufacturer’s recommended dual air. Air restriction gauge, dash-mounted or approved equal. |

|

|

2.16 Included |

Turbo, injectors, starter, and alternator. Automatic engine shutdown system with low oil pressure, high coolant temperature, and low coolant level. |

|

|

3) Clutch and Transmission |

3.1 Operation of Transmission |

Manual with synchromesh |

|

3.2 Hydraulic, Clutch Actuation |

Hydraulic operating with air assistance |

|

|

3.3 Clutch Type |

Φ430 diaphragm-spring clutch, hydraulically operating with air assistance |

|

|

3.4 Number of Speeds of Transmission |

9F+1R Ratio:12.11, 8.08, 5.96, 4.42, 3.36, 2.41, 1.77, 1.32, 1.00, 12.66(R1) |

|

|

3.6 Fuel Type of Transmission |

Diesel |

|

|

3.7 Model/Make of Transmission |

FAST/9JS119T-B(Q) |

|

|

3.8 Fuel type |

Diesel |

|

|

4) Brakes and Tyres |

4.1 Brakes |

Hydraulic-pneumatic assisted, dual circuit, pressure-air, air dryer. |

|

4.2 Brake Type |

Drum brake with ABS |

|

|

4.3 Tire Size |

11.00R20 |

|

|

4.4 Total Number of Wheels with Spare |

6 wheels and 1spare |

|

|

4.5 Service Brake |

Dual circuit pressure-air brake acting on wheels of all axles. |

|

|

4.6 Emergency Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.7 Parking Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.8 Auxiliary Brake |

Engine brake, flap type exhaust brake. |

|

|

5) Suspension |

5.1 Front Type |

Vertical leaf spring + barrel shock absorber |

|

5.2 Rear Type |

Longitudinal main and auxiliary leaf springs |

|

|

6) Cab |

6.1 Type |

4-point full-floating air suspension, with 1 sleeper |

|

6.2 Installed |

Air-conditioned, audio system |

|

|

6.3 Passengers Allowed |

2+1 persons |

|

|

6.4 Color |

Based on requirement |

|

|

6.5 Safety Belts |

Installed |

|

|

7) Axles |

7.1 Loading Capacity of Front |

6.5T |

|

7.2 Loading Capacity of Rear |

11.5T

|

|

|

8) Electrical System on Chassis |

8.1 Working Voltage |

24V, negative grounded |

|

8.2 Starter |

24V, 5.5kw |

|

|

8.3 Alternator |

3-phase, 28V |

|

|

8.4 Battery Type |

2 x 12V -165A.H |

|

|

9) Body and Compaction System

|

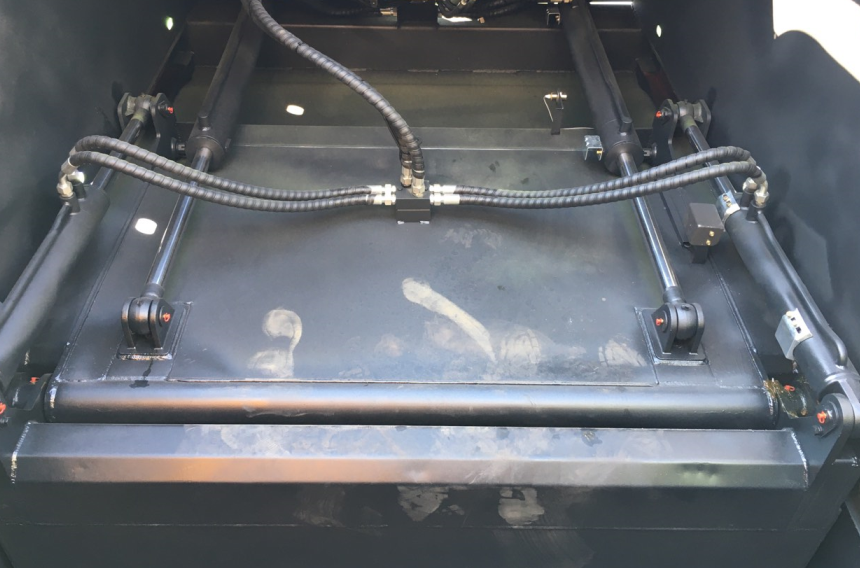

9.1 Picture |

|

|

9.2 Total Internal Volume |

14m³ | |

|

9.3 Garbage Container |

High corrosion resistance Q235 carbon steel 5mm thickness of body floor, 4mm thickness of side and roof. (equivalent as IS-2062 Grade A or ASTM a36) |

|

|

9.4 Hopper Floor

|

NM450 (similar to HARDOX) wear-resistant, high-tensile steel sheet. |

|

|

9.5 Tailgate Sheet

|

High tensile steel sheet 4 mm thickness |

|

|

9.6 Press Panel

|

High tensile steel sheet 5 mm thickness |

|

|

9.7 Ejector Blade

|

High tensile steel sheet 4 mm thickness |

|

|

9.8 Sludge Tank

|

Sewage water relieves of sludge tank of capacity under the garbage tank and tailgate with a leakproof discharging outlet.

|

|

|

9.9 Compaction ratio

|

0.6~0.8T/m3 (Two-way compression) |

|

|

9.10 Safety Device |

The rear camera is connected to the cabinet screen device and movement safety. |

|

|

10) Containers Lifting Devices

|

10.1 Picture |

|

|

10.2 Working Principal |

High capacity articulated arm lifting device works in two stages by four double effects hydraulic cylinders to ensure the lifting and lowering of containers smoothly.

|

|

|

10.3 Lifting Device

|

Can lift standard 120L/240L/660/770/1100L steel and plastic containers. Lifting weight capacity not less than 800 kg (All lifting device arms and parts are made of High Strength Steel). |

|

|

11) Hydraulic System |

11.1 Hydraulic Cylinder

|

Reinforced cylinders, maintenance free. Adopts top brand with durability, high precision. The sealing rings are high quality no oil leakage, pressure instability, or other problems. Multi-stage cylinder for push function: 1pcs Cylinder for compaction function: 2pcs Cylinder for slide function: 2pcs Cylinder for bin lifters: 2pcs Cylinder for tailgate lifting: 2pcs |

|

11.2 Hydraulic Pipe

|

Galvanized steel hydraulic pipe, reliable and long service life. |

|

|

11.3 Hydraulic Control Valve

|

It is the core component of the control system, and all hydraulic cylinder actions are regulated through this valve group. The multi-way reversing valve has fine workmanship and small size. The valve stem is made of 40Gr material, which has high precision and wear resistance. |

|

|

12) Painting / Finishing |

12.1 Both Painted |

The exterior and interior of the tank are spray painted with high-quality painting |

|

12.2 Exterior |

Spray-painted with two coats of superior quality anti-corrosive primer and two coats of enamel metal paint of a reputed make, the exterior surfaces color is painted as required |

|

|

12.3 Sludge Compartment Tank |

Internally coated with two coats of epoxy paint to resist corrosion due to weak acids. |

|

|

12.4 Under Chassis |

Coated with anti-corrosion. |

|

|

13) Controls |

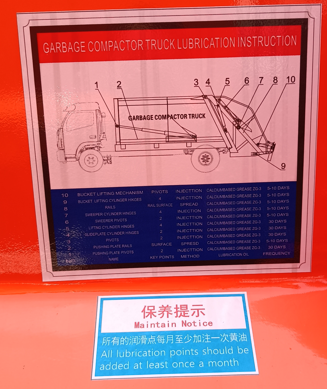

13.1 Picture |

|

|

13.2 Control System |

The system is controlled from the PLC control box, which enables, start, stop, 1-cycle, continuous cycles, and rescue activities. Tailgate and ejector controls are in front of the body. All devices for loading control are mounted on the tailgate right side, and all are manual control for safety purposes. Compaction is controlled electrically via push-buttons, and manually in case. There is an emergency stop button on each of side the truck on the control panel. |

|

|

13.3 Hydraulic Control Valve

|

It is the core component of the control system, and all hydraulic cylinder actions must be regulated through this valve group. Adopting top brand hydraulic control valve, stable performance, low failure rate. |

|

|

13.4 Electric Control Box

|

The automatic control unit, compared with the previous electronic control, is waterproof, and more convenient to use. With the multi-function operation of a garbage truck. |

|

|

13.5 In-cab Control

|

In-cab controls the unloading, and safety operation. |

|

|

14) Safety Devices and Props

|

14.1 Type

|

The tailgate is provided with safety props between the body and the tailgate for safety purposes during maintenance or cleaning.

Standard Balance Valve, ensure the stability and safety of oil cylinder operation.

One Button Emergency Stop

Warning and Safety Tips

The rear control box operates the garbage loading and the in-cab controls the unloading, and safety operation. |