Make & Model: CSCTRUCK / CSJ12EQ290L6.

Drive Type: 6×4.

Gross Vehicle Weight: 25,000kg

Capacity Weight: 10,685kg

Wheelbase: 4,350+1,350mm

Engine Make/Model: CUMMINS / D6.7NS6B290.

Fuel: Diesel.

Emission Standard: Euro 6.

|

|

|

|

Description

BRIEF

The CSCTRUCK combined vacuum unit tankers revolutionize the field by amalgamating the functionalities of both a jetting truck and a sewer tanker. This innovative vehicle offers a comprehensive range of capabilities, including washing, dredging, and sewage suction. By encompassing these diverse tasks, it minimizes the need significantly for multiple vehicles and personnel, as well as the frequency of round trips. Consequently, the combined vacuum unit tankers substantially enhance work efficiency, saving valuable time and reducing costs.

Primarily designed for urban environments, these versatile tankers excel in the suction, transportation, and unloading of various materials such as sewage, sludge, sand and gravel, and even large obstructions found in underground sewage pipes, rainwater wells, and manholes. The advantages of the combined vacuum unit tankers extend beyond urban settings, as they can also be effectively deployed to handle the sewage and industrial waste generated by large factories and mines. Moreover, they are adept at facilitating the suction and transportation of oil and wastewater, as well as the dredging and clearing of small rivers.

By offering such a wide array of functionalities in a single vehicle, the combined vacuum unit tankers represent a significant advancement in efficiency and effectiveness. Their ability to integrate multiple tasks into one streamlined operation allows for improved resource allocation, reduced operational complexity, and enhanced productivity. These tankers enable organizations to optimize their operations, thereby achieving greater environmental sustainability and operational excellence.

In conclusion, the CSCTRUCK combined vacuum unit tankers epitomize a groundbreaking solution for diverse industries. Their multifunctionality, encompassing washing, dredging, and sewage suction, empowers organizations to accomplish their tasks more efficiently while minimizing costs. Whether it’s the unloading of urban sewage systems or the management of industrial waste, these tankers serve as versatile and indispensable assets, revolutionizing the way tasks are undertaken.

FEATURES

– The Dongfeng 12,000 litter combined sewer jetting truck ensures safety and reliability, effectively reducing the workload of the operators.

– Hydraulic technology is used to retract and release the jetting hose in the Hose Reel, enabling repeated dredging and cleaning of the sewer for enhanced cleaning results.

– The CSCTRUCK combined vacuum unit tanker is equipped with a low water level protection system that alerts and reduces engine speed automatically when the tank’s water level is low. This prevents the high-pressure pump from running dry and safeguards the jetting pump.

– The CSCTRUCK combined vacuum unit tanker features a fashionable design that showcases stylish aesthetics. Its human-centered and visually appealing details demonstrate unique creativity. Additionally, it offers excellent value for money and a comprehensive after-sales service guarantee system.

SPECIFICATION

|

PARTS |

ITEM |

DESCRIPTION |

|

General Information

|

1.1 Make & Model |

CSCTRUCK / CSJ12EQ290L6 |

|

1.2 Date of Manufacturing |

2023 |

|

|

1.3 Country of Origin |

China |

|

|

1.4 Truck’s Capable of Operating |

Capable of operating in tropical condition |

|

|

1.5 Most Suitable for Operating |

On both “on and off” road conditions |

|

|

1.6 Truck Unit’s Status |

Brand new |

|

|

1.7 Drive Type |

6×4 |

|

|

1.8 Overall Dimension (L x W x H) |

10,100 x 2,500 x 3,600mm |

|

|

1.9 Gross Vehicle Weight |

25,000kg |

|

|

1.10 Curb Weight |

13,800kg |

|

|

1.11 Capacity Weight |

10,685kg |

|

|

1.12 Wheelbase |

4,350+1,350mm |

|

|

1.13 Max. Speed |

89km/h |

|

|

1.14 Fuel Tank Capacity |

400L |

|

|

1.15 Air Over Hydraulic System |

Chassis’ system is air over hydraulic |

|

|

1.16 Rear Tow/Pintail Hook |

Installed |

|

|

1.17 Standard Tool Kit |

Supplied |

|

|

1.18 Mud Flaps |

Installed |

|

|

1.19 Chassis Designed |

Chassis is adequately designed and strengthened to accommodate the load-body and all associated equipment; and designed to heavy duty export specs, capable of operating in tropical conditions over paved and unpaved roads |

|

|

Engine

|

2.1 Make / Model |

CUMMINS / D6.7NS6B290 |

|

2.2 Country of Origin |

China |

|

|

2.3 Literature and Engine Performance Curves |

Provided documents |

|

|

2.4 Type |

6 cylinders in line, 4 strokes direct injection, water cooling, Intercooler Turbocharged, heavy duty, |

|

|

2.5 Air Intake |

Turbo-charged |

|

|

2.6 Fuel |

Diesel |

|

|

2.7 Cooling System |

Water cooling system |

|

|

2.8 Displacement |

6,700cc |

|

|

2.9 Nominal Power |

290HP (213kW) @ 2,300rpm |

|

|

2.10 Peak Torque |

1,100N.m@1,100rpm |

|

|

2.11 Emission Standard |

Euro 6 |

|

|

2.12 Used |

Engine is used to power the remaining system through a hydrostatic drive and all components through a hydrostatic drive. |

|

|

2.13 Electronics |

The engine electronics accept a remote variable throttle for stationary operation through transmission mounted PTO and transfer case-driven PTO equipment. The air cleaner is to be manufacturers recommended duel air. Air restriction gauge, dash mounted or approved equal. |

|

|

2.14 Included |

Turbo, injectors, starter, and alternator. Automatic engine shutdown system with low oil pressure, high coolant temperature, and low coolant level. |

|

|

3) Clutch and Transmission

|

3.1 Operation of Transmission |

Manual with synchromesh |

|

3.2 Hydraulic, Cltuch Actuation |

Hydraulic operating with air assistance |

|

|

3.3 Clutch Type |

Single dry plate dry coil-spring clutch, Diameter: 430mm, diaphragm type clutch |

|

|

3.4 Number of Speeds. Min. (6F, 1R) of Transmission |

9F,1R Ratio: 11.02, 6.55, 4.64, 3.36, 2.46, 1.95, 1.38, 1, 0.73, 11.52(R1) |

|

|

3.5 Hydraulic Power Steering |

Hydraulic power steering, left hand drive |

|

|

3.6 Fuel Type of Transmission |

Diesel |

|

|

3.7 Model/Make of Transmission |

FAST / 9JS119TA |

|

|

4) Brakes and Tyres

|

4.1 Brakes |

Hydraulic-pneumatic assisted, dual circuit, pressure-air, air dryer. |

|

4.2 Brake Type |

Drum brake with ABS |

|

|

4.3 Tire Size |

295/80R22.5 |

|

|

4.4 Total Number of Wheels with Spare |

10wheels and 1spare |

|

|

4.5 Service Brake |

Dual circuit pressure-air brake acting on wheels of all axles. |

|

|

4.6 Emergency Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.7 Parking Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.8 Auxiliary Brake |

Engine brake, flap type exhaust brake. |

|

|

5) Suspension

|

5.1 Front Type |

Heavy duty leaf springs with telescopic shock absorbers at front |

|

5.2 Rear Type |

Heavy duty leaf springs |

|

|

6) Cab

|

6.1 Type |

4 point full-floating air suspension, with 1 sleeper |

|

6.2 Installed |

Air conditioned, audio system |

|

|

6.3 Passengers Allowed |

2persons |

|

|

6.4 Color |

Based on requirement |

|

|

6.5 Top |

Orange rotating beacon light on top |

|

|

6.6 Safety Belts |

Installed |

|

|

7) Axles

|

7.1 Loading Capacity of Front |

7,000kg |

|

7.2 Loading Capcity of Rear |

18,000kgx2 |

|

|

8) Electrical System on Chassis

|

8.1 Working Voltage |

24V, negative grounded |

|

8.2 Starter |

24V, 7.5kw |

|

|

8.3 Alternator |

3-phase, 28V |

|

|

8.4 Battery Type |

2 x 12V -165A.H |

|

|

9) Combined Sludge and Clean Tank

|

9.1 Tipping |

The tank is mounted with an arrangement for rear tipping |

|

9.2 Total Internal Volume |

12,000liters |

|

|

9.3 Material |

High quality mild steel model Q235 (equivalent as IS-2062 Grade A or ASTM a36) |

|

|

9.4 Thickness |

6mm |

|

|

9.5 Division of Compartment |

Tank is divided in two compartments. Cleaning water tank compartment: 4,000liters Sludge/sewage tank compartment: 8,000liters |

|

|

9.6 Level Indicators |

Material: Transparent acrylic tubing with thick wall Quantities: Total two units. One on each of compartment. |

|

|

9.7 Ladder |

Location: On the tank to access to the top of the tank. Designed to withstand conditions prevailing from the operating vacuum and pressure conditions. |

|

|

9.8 Hydraulic Connections |

All hydraulic connections are a combination of high-pressure pipes and flexible hoses, to facilitate easy replacements/repairs. |

|

|

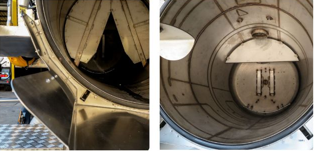

9.9 Rear Door |

Fully open able type It is reinforced for structural integrity. Raised to angle of 80°to the vertical. Locking and sealing (no leakage) is done by hand wheel operated bolts, which are a robust design located circumferentially on the tank’s rear end of the shell. Liquid tight by means of a self-compensating seal, and is locked by means of four manual latches.

|

|

|

9.10 Circular Cross & Baffles |

Circular cross # section with dished end baffles based on design of tank

|

|

|

9.11 Channels |

Reinforcing channel around outer periphery when it is necessary |

|

|

9.12 Tank Testing |

The tank is hydrostatically tested. |

|

|

9.13 Sight Glass |

The tank is provided with 2-sight glass located at the end dish of the tank to measure the volume of sewage inside the tank. Sight glass is tempered-proof material and is easily replaced.

|

|

|

9.14 Automatic Sensing Device |

Automatic sensing device to prevent overfilling (sniffer valve releasing vacuum when tank is full). |

|

|

10) Painting / Finishing

|

10.1 Both Painted |

Exterior and interior of the tank is spray painted with high quality painting |

|

10.2 Exterior |

Spray-painted with two coats of superior quality anti-corrosive primer and two coats of enamel metal paint of a reputed make |

|

|

10.3 Sludge Compartment Tank |

Internally coated with two coats of epoxy paint to resist corrosion due to weak acids. |

|

|

10.4 Under Chassis |

Coated with anti-corrosion. |

|

|

11) Cleaning Water Compartment

|

11.1 2” Ball Valve |

1No. 2” ball valve at the forward end of the compartment to facilitate draining |

|

11.2 3” Ball Valve |

1No. 3” ball valve to isolate the tank from the jetting system to facilitate maintenance even with a water-filled tank |

|

|

11.3 Level Glass |

Fitted on a suitable position to enable the operator to gauge the content’s level inside the tank |

|

|

11.4 Manhole |

For tank filling and to allow man-entry in the tank for routine cleaning and inspection |

|

|

11.5 Breather |

A tank breather is fitted on the tank top to allow the compartment to be constantly vented to the atmosphere during jetting operations.

|

|

|

12) Sludge Compartment

|

12.1 Knife Gate Valve |

1No. 100mm knife gate valve located at the bottom most position at the rear dished end for draining the tank’s contents. |

|

12.2 Level Glass |

Fitted on a suitable position to enable the operator to gauge the content’s level inside the tank. |

|

|

12.3 Primary Shut-off |

A ball float type, primary shut-off to prevent water from entering the pumping system due to an accidental overflow. |

|

|

12.4 Vacuum Relief Valve |

1No. installed |

|

|

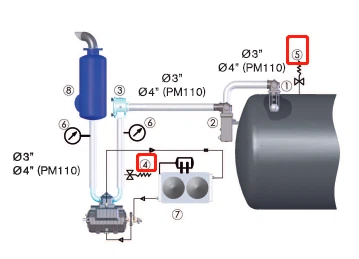

13) High Pressure Jetting Pump

|

13.1 Make |

PINFL |

|

13.2 Model |

MGS50 |

|

|

13.3 Country of Origin |

Germany |

|

|

13.4 Type |

Heavy-duty positive displacement single acting triplex reciprocating pump to be driven by a split shaft from total power take off unit. |

|

|

13.5 System |

The system is adequately protected by incorporating suitable pressure relief valve & unloader valve, water filter and pneumatically actuated three-way valves. |

|

|

13.6 Pump Rated Power Output |

137kw |

|

|

13.7 Pressure Drive |

250bar |

|

|

13.8 Scavenging Capacity |

287l/min |

|

|

13.9 Drive |

Drive for the high-pressure jetting pump, as also the vacuum pump is tapped from a new generation total power take off (split shaft P.T.O.). |

|

|

14) Hose, Hose Reel, Nozzles and Accessories

|

14.1 Make & Material |

Equivalents Polyose/Parker/Aeroquip & Thermoplastic |

|

14.2 Hose Reel and Hose |

On the rear end of the Combined tank is provided of the hose’s reel, and is designed to store up to 120 meters of the supplied sewer jetting hose 1″. Delivery and recovery of the jetting hose is done via a low speed, high torque hydraulic. Reel installed at rear of truck, and reel can +-160ratoted |

|

|

14.3 Hose |

Hose with 1” (inch) dia. & 120 meters long male end, bore to withstand a working pressure 170bar, and bursting pressure of 400bar of light weight and war resistant thermoplastic material. |

|

|

14.4 Safety Valve |

Installed |

|

|

14.5 Pressure Regulator |

Installed |

|

|

14.6 Suction Strainer |

Installed |

|

|

14.7 High Pressure Jetting Nozzles |

1” (inch) female thread, high pressure jetting nozzles working pressure 165bar (milling type, torpedo type, sewer cleaning type)

Nozzles photos for reference only |

|

|

14.8 Extra Hose Rubber |

On the rear carrying 10 meters of 25mm diameter hose rubber braided for maintenance work and standard hand gun with a suitable stowage arrangement |

|

|

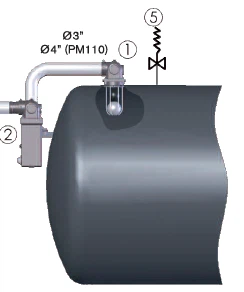

15) Vacuum Pump

|

15.1 Make |

MORO |

|

15.2 Model |

PM100W |

|

|

15.3 Country of Origin |

Italy |

|

|

15.4 Pump Capacity |

16,400Lt/min |

|

|

15.5 Cont. Duty Vacuum |

80% |

|

|

15.6 Maximum Vacuum |

95% |

|

|

15.7 Suction Depth |

Aspiration of the effluent from sewer and drain water lines and chambers are carried out on the principle of generating high vacuum in the sludge compartment for siphoning out effluents, liquids slurry, sludge and other materials from depths of 6 meter. |

|

|

15.8 Type |

Water cooled vacuum pump, heavy duty/multi-cylinder type, strong high-pressure, continuous duty. It fitted with a rotary sliding vane, positive displacement type exhauster/compressor. |

|

|

15.9 Max. Exhaust Power |

41kw |

|

|

15.10 Rotated Speed |

1,400rpm |

|

|

15.11 Lubrication |

Automatic lubrication with drip oilers and sight glasses |

|

|

15.12 Driven Method |

Vacuum pump can be driven by auxiliary engine, but we advise to install the new generation split shaft P-T-O which can drive vacuum pump and jetting pump. |

|

|

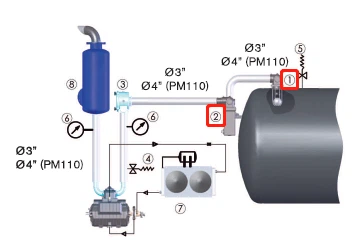

16) Suction Hose, Hose Connection and Accessories

|

16.1 Pressure Relief Valve |

Installed/ Pressure Relief Valve – Fitted in a suitable position, this device provides safety to the storage tank as the complete system. The valve is of a spring-loaded adjustable type and provides continuous relief when the system’s pressure exceeds the preset limit.

|

|

16.2 Pressure(vacuum) Relief Valve |

Installed |

|

|

16.3 Suction Filter |

Installed

|

|

|

16.4 Exhaust Silencer |

Installed / Exhauster is directly driven from cab-controlled P.T.O (it means the reverse discharge of vacuum pump and pumping & charging into tank are driven by split-shaft P.T.O which controlled in the cab.)

|

|

|

16.5 Primary & Secondary Shut-off |

Installed

|

|

|

16.6 A Suction Group Pneumatically operated 4-way |

Installed |

|

|

16.7 Heavy Duty Spiral Suction Hoses |

Provided with heavy Duty spiral suction hoses, 6″ diameter. The hose is 15 meters in length with aluminum or galvanized steel light and easy to handle PVC hose along with quick-connect fittings on each end and provided with male-female couplings for the suction application |

|

|

16.8 Attached of Sections |

Sections are flanged and attach by quick-coupler |

|

|

16.9 Valve (for A Suction-Pressure Position) |

It is non-return valve and initially installed by MORO. |

|

|

16.10 A Suction Hose End Nozzle |

A 150 mm dia. a suction hose end nozzle attached to one of the hoses and a suction end 150 mm strainer both fitted with suitable quick release couplings are provided with the equipment as standard accessory. |

|

|

16.11 Hose Trays |

It is provided with check red plate hose trays, one on each side of the tank and extending along the full length of the tank, capable of securely holding the quantity of 150mm hoses. |

|

|

16.12 Bolts and Nuts |

All bolts and nuts with direct contact to sludge are made of 304 stainless-steel materials. |

|

|

16.13 No-Bend of Discharge or Suction Port |

Not having 90 degrees bend for the discharge or suction port to prevent any clogging of sands and grits. |

|

|

17) Controls

|

17.1 Control Panel |

The system is driven by a control panel fixed on the backside of the tank and remote control for boom system. All controls for the operation and of the workings of the truck are fitted to an illuminated, lockable, water-resistant control panel that is attached and moves with the hose reel. |

|

17.2 Electrical Switches on Control Panel |

The intention is for all controls in the control panel to be electrical switches that activates the necessary function and servos either pneumatic or hydraulic and all actions will be fully adjustable and at variable speeds for the operation of the machine |

|

|

17.3 Servos and Valves |

All servos and valves are mounted in a safe and easily accessible place for ease of maintenance. All electrical devices are splash resistant. |

|

|

17.4 All Necessary Controls & Gauges |

The truck and the unit system are furnished with all necessary controls & gauges. / Safety devices for improved efficiency and easy – safe operation, / Orange rotating beacon light on top. |

|

|

18) Split Shaft P-T-O

|

18.1 Quantity |

1pc |

|

18.2 Origin |

China |

|

|

18.3 Type |

High quality new generation split shaft P-T-O drive for the high-pressure jetting pump, as also for the vacuum pump. Or auxiliary engine installed to drive vacuum pump, while P-T-O drives high-pressure jetting pump. |