Model NO.: FRP Insulated Truck Box Refrigerated Truck Body.

External Dimensions: As per your request. Length From 3.2m to 9.6m.

Package Size: 450.00cm x 220.00cm x 220.00cm

Package Gross Weight: 1200.00kg

|

|

|

|

Description

BRIEF

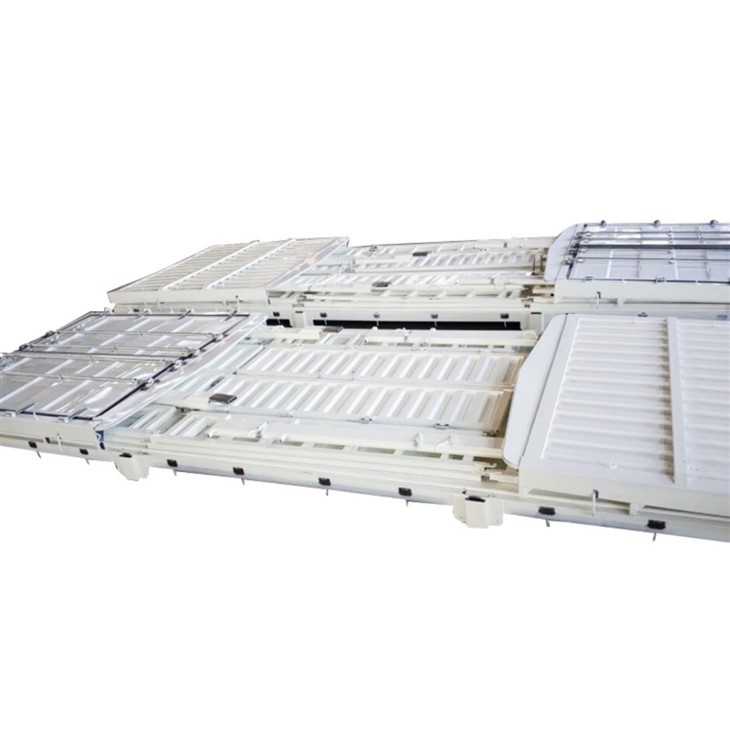

The “FRP Insulated Truck Box Refrigerated Truck Body” represents a cutting-edge innovation in the field of transportation and refrigeration.

FRP, which stands for Fiber-Reinforced Plastic, is a versatile material that is used to construct insulated truck boxes for refrigerated trucks. It has gained popularity in the industry due to its exceptional insulation properties, durability, and lightweight nature. These attributes make it the ideal choice for maintaining a consistent and controlled temperature within the truck body, ensuring the safe transport of temperature-sensitive goods.

The insulation within the truck box is of paramount importance when it comes to refrigerated transportation. The FRP-insulated truck box excels in maintaining the desired temperature, whether it’s freezing or chilling, irrespective of external weather conditions. This ability to keep the cargo at the optimal temperature ensures the quality and safety of perishable goods during transit, reducing the risk of spoilage and maintaining the integrity of the products being transported.

Additionally, the lightweight nature of FRP contributes to fuel efficiency, reducing the operational costs for trucking companies. This means lower fuel consumption and reduced emissions, aligning with the industry’s growing focus on sustainability and environmental responsibility.

The “FRP Insulated Truck Box Refrigerated Truck Body” is also renowned for its robustness and longevity. It can withstand the rigors of long-haul transportation, ensuring that your investment in this technology is a durable one. With a lower risk of wear and tear, maintenance costs are reduced, making it a cost-effective choice for businesses in the long run.

FEATURES

1. Advanced Insulation Technology: The “FRP Insulated Truck Box Refrigerated Truck Body” features state-of-the-art Fiber-Reinforced Plastic (FRP) insulation technology. This advanced material offers superior thermal efficiency, ensuring that temperature-sensitive cargo is maintained at the desired temperature, even in extreme environmental conditions.

2. Customizable Size and Configuration: This refrigerated truck body is available in a range of sizes and configurations to meet the diverse needs of businesses. Whether you need a compact delivery vehicle or a spacious refrigerated truck, this product can be customized to accommodate your specific requirements.

3. Energy-Efficient Refrigeration: The refrigeration system integrated into this truck body is designed for energy efficiency. It employs the latest technology to minimize power consumption, reducing operational costs and environmental impact. Additionally, the system is engineered to maintain precise temperature control throughout the entire cargo area.

4. Durable and Lightweight Construction: The use of FRP materials in the construction of this truck body ensures a high level of durability without adding unnecessary weight. This results in increased payload capacity and fuel efficiency, making it a cost-effective and eco-friendly solution for transporting perishable goods.

5. Easy Maintenance and Hygiene: The FRP construction not only provides durability but also makes the truck body easy to clean and maintain. The smooth and non-porous surface is resistant to corrosion, rust, and contamination, ensuring a clean and sanitary environment for transporting food, pharmaceuticals, or other temperature-sensitive goods.

SPECIFICATION

| XPS Insulated Reefer Truck Body | |

| External Dimensions | As per your request. Length From 3.2m to 9.6m |

| Specification Of Base Panel | |

| Panel Thickness | 70mm |

| Material Of Outside Wall | Smooth Fiberglass Sheet Thickness 2.2mm |

| Material Of Insulation | Fiberglass 2.2 + XPS 70 + Waterproof Plywood 16 + Fiberglass 2.2 |

| Cross Member | Painted Steel Cross Beam 80mm X 40mm X 3mm |

| Specification Of Wall Panel | |

| Panel Thickness | 45/ 70mm |

| Material Of Outside Wall | Smooth Fiberglass Sheet Thickness 2.2mm |

| Material Of Insulation | Fiberglass 2.2 + XPS 45/70 + Fiberglass 2.2 |

| Material Inside Wall | Smooth Fiberglass Sheet Thickness 2.2mm |

| Specification Of Door Panel | |

| Panel Thickness | 70mm |

| Material Of Outside Wall | Smooth Fiberglass Sheet Thickness 2.2mm |

| Material Of Insulation | Fiberglass 2.2 + XPS 70 + Fiberglass 2.2 |

| Material Inside Wall | Smooth Fiberglass Sheet Thickness 2.5mm |

| Accessories Standard | Front Led Lamp 2 Pcs |

| Rear Led Lamp 2 Pcs | |

| 2 Rear Doors | |

| SS304 Stainless Steel Door Frame | |

| SS304 Stainless Steel Door Lock Parts | |

| Aluminium Profile And Wrap Angle | |

| Optional | Side Door And Door Plastic Curtain |

| Aluminum Checker Floor | |

| Aluminum Kick Panel | |

| T Shape Rail Aluminum Floor | |

| OEM Service | Yes |

XPS Panel Advantage:

- Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used for 35-50 years.

- Resistance to compression: Compared with other thermal insulation materials (200Kpa for EPS), it has better compressive strength(around 300Kpa), which makes it the ideal solution for heavy domestic or industrial loads.

- Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture.

- Lightweight: volume optimization and easy to handle.

- Resistance to deformation

- Resistance to impact

- Versatile: The closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape 100% ozone-friendly.