Chassis brand: ISUZU QL5350THBW1SDZY

Firefighting Pump: HALE (MADE IN GERMANY)

Firefighting Monitor: Akron PLKD10/80B-5177(MADE IN GERMANY)

Foam System: Negative round the pump of 6% (manual)

Volume: 2000L (water)

Ladder: Fast hoisting drive, six-section synchronous telescopic truss ladder

Description

Description:

The fourth-generation ISUZU YT54 aerial ladder firefighting truck boasts a new ladder structure design, enhancing its performance and bringing it closer to actual firefighting scenarios. This high-end flagship product comprises a chassis, sub-frame, power take-off device, assembly and lifting system, water system, hydraulic system, electrical system, and safety device.

Structure:

Composed of various elements, the ladder fire truck mainly consists of a chassis, sub-frame, power take-off device, assembly and lifting system, water system, hydraulic system, electrical system, and safety device.

Function:

The vehicle’s impressive high-altitude rescue capabilities include a 300kg ladder cage capacity, 54m working height, and a maximum working range of 18m. It features a special sliding cage rescue system with a 180kg capacity, enabling it to rescue trapped individuals from 54m to the bottom without repeating the ladder lifting action, making it practical and efficient. The efficient water system provides large flow, low-pressure loss, and high fire extinguishing efficiency, and the vehicle has several safety protection technologies to prevent dangerous working conditions and ensure safety and reliability.

Advantages:

As the leading Ladder Fire Truck Manufacturer for firefighting and disaster protection systems in China, CSCTRUCK provides uncompromised quality and maximum safety to response teams worldwide. With an experienced research team, we ensure the highest series quality for custom orders.

SPECIFICATION

|

Operating Performance Spec. |

|

|

Brand |

ISUZU |

|

Outrigger Span(V x H) |

5200±50 |

|

Max Working Height |

54m |

|

Max Working Outreach |

18m |

|

Cage Rated Capacity |

300kg |

|

Slide cage-rated capacity |

180kg |

|

Boom operating time |

≤120s |

|

Slide cage speed |

≥0.8m/s |

|

Outrigger leveling time |

≤30s |

|

Max allowed wind speed |

≤12.5(level 6)m/s |

|

Driving Performance Spec |

|

|

Full Load Weight |

≤32000kg |

|

Power |

308kw |

|

Cab Seat |

2p |

|

Emission Standard |

National/Euro V |

|

Fire Operating Performance Spec |

|

|

Max flowing of water pump |

5400L/min |

|

Flowing of fire pump vehicle system |

[email protected] L/min@MPa |

|

Max flowing of fire monitor |

[email protected] L/min@MPa |

|

Flowing of fire monitor vehicle system |

[email protected] L/min@MPa |

|

Tank Volume |

2000L |

|

Rated spraying reach of fire monitor |

65m |

|

Fire Monitor Rotation Angle |

-45~+45° |

|

Fire Monitor Pitch Angle |

-45~+90° |

Chassis |

|

|

Chassis model |

ISUZU QL5350THBW1SDZY 6×4 |

|

Engine Model |

6WG-1TCG52 Inline six-cylinder turbo charge diesel engine |

|

Engine power |

308Kw@1800r/min |

|

Engine Torque |

2060N.m@830-1400r/min |

|

Max speed |

100km/h |

|

Wheel torque |

4800mm+1370mm |

|

Emission standard |

National Ⅴ |

|

Gearbox |

Manual |

|

Electric system |

Generator:1.7kw/28V; Battery: 2x12V/120Ah |

|

Fuel system |

≥300L |

|

Braking system |

Service brake: double circle brake; |

|

Parking brake: spring actuated and air cut off parking brake;

|

|

|

Assist brake: engine exhaust brake;

|

|

|

With ABS system |

|

|

Tire |

385/65R22.5; 315/80R22.5 |

Superstructure |

|

Cage |

|

|

Rescue cage overview |

Automatically flip over the inverted ladder; Automatically deployment and leveling; Equipped with working light and safety rope |

|

Cage rated capacity-outreach |

300kg-18m, 200kg-19m;100kg-20m |

|

Platform area |

1.29m2 |

|

Leveling Method |

The electro-hydraulic intelligent independent leveling system |

|

Self-protection spray flow |

≥285L/min |

|

Ladder |

|

|

Section |

Six Sections |

|

Main material |

Special high-strength shaped pipe |

|

Telescopic mechanism |

Winch+ imported high flexible steel wire rope and pulley block to achieve synchronous telescopic |

|

Operation curve |

See chart |

|

Ladder operation model |

Footswitch + handle step-less control; electronic control forced operation; manual forced operation |

|

Turntable |

Water, electricity, and hydraulic integrated central rotary device, any 360 continuous rotation |

|

Outrigger |

|

|

Type |

H-Type |

|

Horizontal Span |

5200±50mm |

|

Outrigger operation mode |

Automatic unfolding; Electronic control + manual; Manual forced |

|

Slide cage |

|

|

Overview |

Frame folding structure, aluminum alloy door, folding in the upper part of the ladder when driving |

|

Driving type |

Hydraulic motor-driven winch, Drive the wire rope through the pulley block |

|

Max speed of slide cage lifting |

≥0.8m/s |

|

Slide cage-rated capacity |

180kg |

|

Slide cage working at a variable Angle |

50°~75° |

|

Platform area |

≥0.8m2 |

|

Slide cage brake |

Mechanical friction brake |

Waterway System |

|

|

Fire monitor Model |

Akron PLKD10/80B-5177 (MADE IN GERMANY) |

|

Water pump model |

HALE CB10/100- RSD (MADE IN GERMANY) |

|

Max flowing of water pump |

5400(L/MIN) |

|

Flowing of water pump vehicle system flow |

[email protected] (L/min@MPa) |

|

Max flowing of fire monitor |

[email protected] (L/min@MPa) |

|

Flowing of water monitor vehicle system flow |

[email protected] (L/min@MPa) |

|

Water pump type |

Electric control of the fire monitor which can achieve working conditions of horizontal rotation, pitch, and water curtain |

|

Tank Volume |

2000L(for water) |

|

Tank material |

High-quality stainless steel, bottom plate thickness 5mm, side plate thickness 4mm, roof 3mm |

|

Telescopic pipe |

High-strength aluminum alloy pipe |

|

Other pipes |

Stainless steel or aluminum alloy |

|

|

|

|

2 Water suctions(Front left and right sides) DN150 |

|

|

2 Water inlet(Front left and right sides) DN80 |

|

|

4 water outlet(Front left and right sides) DN80 |

|

|

1 water outlet(cage front) DN65 |

|

|

1 Extension foam suction DN50 |

|

|

Electrical system |

|

|

Control system |

CAN bus intelligent control system (controller + display screen + control program) |

|

Operating table |

Turntable left operating table (with seats) |

|

Cage operating table |

|

|

Vehicle rear operation panel |

|

|

Screen |

High brightness LCD color display, located in the turntable operation table and cage operating table, Vehicle rear operation panel |

|

Light System |

Cage front left and right sides of the configuration of high-brightness lighting |

|

Yellow warning light around the cage |

|

|

High-intensity lighting on both sides of the ladder |

|

|

Ladder support with high-intensity lighting |

|

|

Turntable console, ladder configuration with channel lighting |

|

|

Each instrument panel is equipped with instrument lighting |

|

|

Equipment box with configuration lighting |

|

|

Outrigger with warning light |

|

|

Outrigger illuminator for illuminating the underside of the leg support |

|

|

Alarm light system |

A circular warning light on the left and right sides of the cab. |

|

Integrated operation of alarm lights and alarms in the cab |

|

|

Various functions such as fire alarm sound, siren sound, and external calls. |

|

|

A square red/blue strobe light on the left and right of the rear of the car. |

|

|

Intercom system |

Turntable and bucket using non-handheld cable intercom system |

|

Cables and connectors |

Adopt the imported connector with waterproof performance up to IP67 |

|

Ladder chain and imported cables |

|

|

Automatic disconnect charging device |

The battery can be charged by 220V mains, and the charging plug will automatically fall off when the fire truck starts |

|

Reversing assist system |

With reversing alarm buzzer, reversing camera, and cab monitor; |

Security protection system |

|

|

Cage overload protection |

When the cage exceeds 10% of the rated load, alarm and stop all actions. |

|

Cage tipped protection |

When the cage tilts more than 7 degrees, cut off all actions. |

|

Cage Anti-collision protection |

When the cage approaches the obstacle, the system alarms and stops the dangerous direction from continuing to approach |

|

Ladder buffer protection |

Limit position and sudden handle, the system can automatically accelerate and decelerate |

|

Ladder limiting protection |

When the ladder turns to the short outrigger, cut off the turning action in the dangerous direction |

|

Rotary buffer protection |

The system can effectively realize buffering when the rotation stops suddenly |

|

Rotary alignment |

When the rotation is close to the middle, Automatic speed reduction to ensure accurate center alignment |

|

When the rotation is close to the middle, Automatic speed reduction to ensure accurate center alignment |

In order to prevent the ladder frame from colliding with the car body, when the ladder frame turns to a certain position, it will automatically stop the dangerous direction of turning. |

|

Interlock |

The outriggers are not unfolded, the booms cannot move; the booms leave the bracket and the outriggers cannot move |

|

Emergency function |

On-board operating valve and outriggers operating valve with the emergency manual operation; The system with an emergency power unit for winding up ladder frames and outriggers in case of engine or oil pump failure. |

|

Outrigger operation alarm |

Outriggers operation, Acousto-optic automatic alarm to prevent people from touching. |

|

Soft outrigger protection |

In ladder operation, the outrigger appeared virtual outrigger and automatically cut off the dangerous direction. |

|

Outrigger tips |

The water cannon inlet pressure exceeds the rated value, an alarm is raised and the engine continues to accelerate. |

|

Water tank protection |

In addition to the overflow port with a large enough aperture, the pressure overflow device at the tank’s mouth is also set to prevent accidental overpressure when the water tank is filled with water |

|

Engine speed limit |

The ladder frame is in motion, the engine speed is automatically limited; The water pump works, preventing overpressure or water pump over speed, automatic limit engine speed |

|

Super wind speed alarm |

The wind speed exceeds 12.5m/s, the acousto-optic system will automatically alarm and cut off the operation to the dangerous direction |

|

Tips for not closing the door of the equipment box |

If the equipment door is not closed, the light will automatically alarm to prevent accidents. |

Hydraulic system

|

|

Hydraulic system

|

Import variable pump + proportional valve load sensitive system

|

|

Max system pressure |

23MPa |

|

Ladder operation valve |

Original imported brand, hydraulic pilot high-performance electromagnetic proportional valve; Automatic adjustment of engine speed when the ladder is operating |

|

Outrigger valve |

Original imported brand, electromagnetic proportional valve; The outrigger operates automatically, and the engine speed increases automatically. |

|

Balance valve and other core valve parts |

Original imported brand |

|

Emergency power unit |

Gasoline engine drive |

|

Oil filter |

Original imported brand, pump outlet of a pipeline oil filter; A return oil filter with filter plug to dispatch instructions |

|

Hydraulic oil specification |

Common area: Mobil DTE 20 Series 24; Low-temperature area: Mobil DTE 10 Excel 32; Extremely cold area: Kunlun No. 10 ground aviation hydraulic oil |

Body |

|

|

Overview |

Light weighted body with strong load capacity and excellent and strong anti-corrosion. Applied with aviation binder on the cover sheets to reduce vibration and noise |

|

Structure |

The body frame is constructed by a high strength aluminum alloy profile with hidden lap joint technology |

|

The body skin is bonded with high-strength structure adhesive |

|

|

Climbing ladder |

Equipped with a fixed ladder on the body’s left and right |

|

Paint |

Fire red paint on the exposed surface of the car body; |

|

Water tank exposed surface paint |

|

|

Anti-corrosion aluminum alloy tread plate on the top of the car body |

|

Others |

|

|

Waterway connector |

|

|

Water suction |

Snap type |

|

Water inlet |

Insertion type |

|

Water outlet |

Insertion type |

|

Rescue cage outlet |

Rescue cage outlet |

|

Foam suction inlet |

Insertion quick coupling |

List of attachments carried in the vehicle |

|

|

Fire hose(Insertion type) |

20-80-20(4) |

|

Shaped quick connector (inner thread) |

KD150/100(1) |

|

Water pipe(snap type) |

φ150×2000(2) |

|

Water pipe wrench |

6″(2) |

|

Water filter (snap type) |

FLF150(1) |

|

Irregular interface |

KXK65 inner/80 female(2) |

|

Hose bandage |

QH16044X(4) |

|

Ground fire hydrant wrench |

FB450(1) |

|

Underground hydrant wrench |

FBA800(1) |

|

Safety harness |

FZL-DD-III(2) |

|

Outrigger pad |

50×500×500(4) |

|

Fire Extinguisher |

MFCZ/ABC3(1) |

|

Quick foam suction pipe |

1 |

|

Foamed pipe |

FPG80(1) |

Operating chart

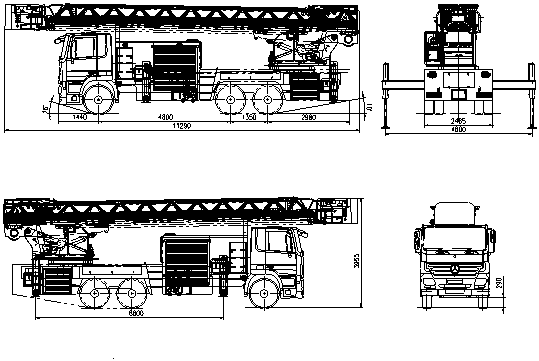

Dimension image (for reference)

|

|