Model No.: Sewer Septic Truck 10m3 Tank Capacity

Sewage Tanker Capacity: 10m3

Chassis Brand: SHACMAN 4×2

Engine Model: CUMMINS 345hp

China’s TOP 3 Vacuum Pump

|

|

|

|

Description

BRIEF

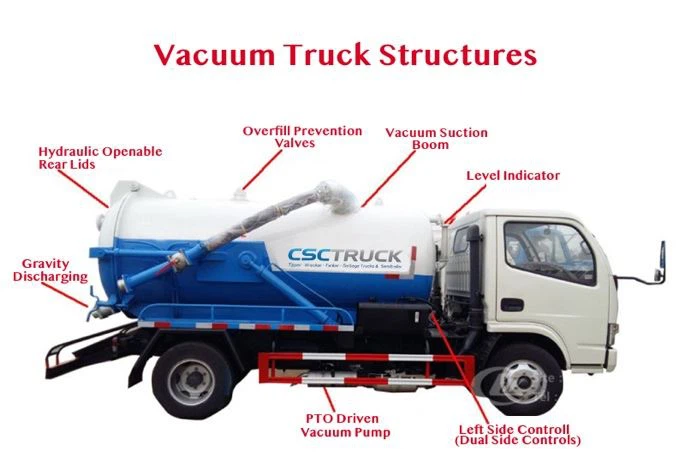

The sewer septic truck 10m3 tank capacity engineered by CSCTRUCK serves the purpose of efficiently gathering sewage and sludge through suction and subsequently transporting it. Built upon the dependable SHACMAN 4×2 truck chassis, this Vacuum Sewer mount boasts a robust design. Its key components include a subframe seamlessly integrated with the truck chassis, a cylindrical tank for containment, a hydraulically operated full-diameter tailgate for convenient access, and a powerful vacuum system driven by the PTO.

Crafted with precision, this specialized vehicle ensures optimal performance in sewage and sludge management tasks. Its design prioritizes functionality and reliability, making it suitable for a variety of industrial and municipal applications. The integration of the vacuum system with the truck’s power take-off mechanism ensures consistent and efficient operation, enhancing productivity while minimizing downtime.

Moreover, the CSCTRUCK sewer septic truck is engineered to meet rigorous standards of durability and performance. Its construction reflects a meticulous attention to detail, ensuring longevity and resilience in demanding operating environments. Whether tasked with routine maintenance in urban areas or handling larger-scale sewage projects, this vehicle is well-equipped to tackle the challenges of waste management effectively.

In essence, the CSCTRUCK sewer septic truck represents a fusion of innovation and practicality, offering a reliable solution for the collection and transportation of sewage and sludge. With its robust design and efficient functionality, it stands as a testament to the company’s commitment to delivering top-tier products tailored to the needs of modern infrastructure and sanitation management.

TRUCK MAP

APPLICATION

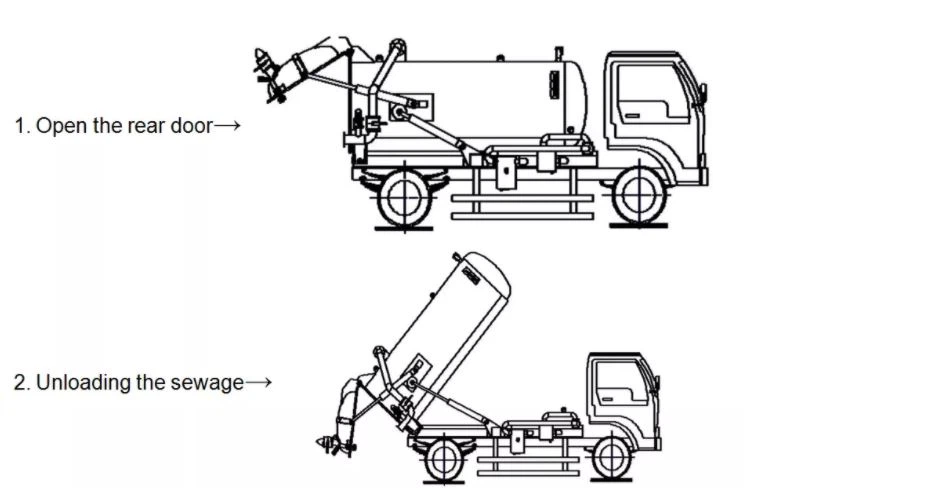

The primary purpose of the sewer septic truck is to facilitate the cleaning of cesspools and the transportation of fecal liquids to designated disposal sites. Its specialized equipment includes a tank, a powered vacuum pump, a signal-safety system, a receiving manhole equipped with a suction hose, control valves along the pipeline, platforms for operation, and supplementary electrical components. The tank is filled through the suction created by the vacuum pump, utilizing either gravity discharge or air pressure generated by the pump.

Vacuum Truck Parameters

|

Parts |

Specification |

|||

|

1) General |

Truck Model |

CSC5182GXWD6 |

||

|

Driving Type |

4×2, Left-hand drive/right-hand drive |

|||

|

Capacity |

10m3/CBM |

|||

|

Chassis Truck brand |

SHACMAN |

|||

|

Color |

Yellow/blue/white |

|||

|

Overall Size(mm) |

6,945×2,490×3,300 |

|||

|

GVW(kg) |

GVW≤20,000 |

|||

|

Curb weight(kg) |

9,500 |

|||

|

Wheelbase(mm) |

4,600 |

|||

|

Oil Tank capacity |

400L, made in aluminum material |

|||

|

Max. speed (km/h) |

95 |

|||

|

2) Engine |

Make/Model : |

CUMMINS ISME345 30, |

||

|

Cylinder No.: |

6 cylinders inline |

|||

|

Max. Output Power: |

254kW (345hp)@1900rpm |

|||

|

Torque: |

1710N.m @ 1000-1200rpm |

|||

|

Type: |

Diesel, supercharged and intercooler(turbocharged), direct injection, electronic control |

|||

|

Emission |

Euro III |

|||

|

3) Transmission |

Make/Model : |

FAST/FAST16JSD220T |

||

|

Gear Numbers: |

16-forwards, 2-reverses, |

|||

|

Type: |

Manual |

|||

|

Synchronizer : |

Yes |

|||

|

Input power |

380kw |

|||

|

Input torque : |

2200N.m |

|||

|

4) Clutch |

Clutch Diameter |

Φ430 mm |

||

|

5) Suspension |

Front |

Semi-elliptic leaf springs with shock absorbers |

||

|

Rear |

Semi-elliptic leaf springs |

|||

|

6) Front Axle |

Type |

Steering axle |

||

|

Number |

1(one) |

|||

|

Rated Axle Loading |

7,500kg |

|||

|

Make |

HANDE(MAN technology) |

|||

|

Brake torque |

31,500N.m |

|||

|

Axle weight |

460kg |

|||

|

7) Rear Axle |

Type |

double reduction drove axle |

||

|

Number |

2 (two) |

|||

|

Rated Axle Loading |

2*13000kg |

|||

|

Make |

HANDE (MAN technology) |

|||

|

Axle weight |

F.R.axle:870kg |

|||

|

R.R.axle:780kg |

||||

|

8) Brake |

Running brake |

Dual circuit compressed air brake |

||

|

Parking brake |

The rear-wheel spring power brake |

|||

|

Assistant brake |

Exhaust braking JACOB |

|||

|

9) Tire |

Size |

315/80R22.5 |

||

|

Brand |

DOUBLE HAPPINESS or equivalent |

|||

|

Type |

Tubeless |

|||

|

Number |

6+1pcs spare tire with spare tire carrier |

|||

|

For road |

Suitable for expressways, ordinary highways, and urban highways. |

|||

|

Type |

Standard cab, One sleeping bed, four-point suspension,

|

|||

|

Equipment 1 |

A/C, |

|||

|

Equipment 2 |

air main seat, |

|||

|

Equipment 3 |

Electric windows, |

|||

|

Equipment 4 |

180Ah free maintenance battery, |

|||

|

Equipment 5 |

radio with USB |

|||

|

10) Emptier tank |

Material |

Q235(equivalent to S235JR )steel plate |

||

|

The thickness of the tank: |

6mm Q235 |

|||

|

Front and rear plate thickness |

6mm Q235 |

|||

|

Tank Style |

Cylindrical type, equipped with splash walls/ baffle plates and reinforced around the circumference. The reservoir will be cylindrical at 6 mm |

|||

|

Coating |

specialized internal chemical coating. |

|||

|

Filling Level Indicator |

Indicator mark on the tank for a maximum and minimum level of Acrylic Sight Glass furnished. There is a level indicator of pipe visibility for dirty water in the back door. |

|||

|

11) Vacuum pump |

Model/Make |

Chinese famous brand with good quality |

||

|

Rotating speed (r/min) |

500 |

|||

|

Absolute working pressure(Pa) |

400Pa |

|||

|

Free Air Flow |

45L/second |

|||

|

Max Vacuum |

99.6%, |

|||

|

Overflowing |

Air pump to safeguard pump from overflowing Sludge tank between the air pump and the tank. |

|||

|

Installation |

The location of the pump installed is very accessible for routine and overhaul maintenance. it is installed by the left side of the emptier tank. |

|||

|

Control |

Four-way-cock for suction and pressure manually controlled, safety valve for maintenance of the pressure |

|||

|

Safety Device |

Safety devices for overflow protection of the vacuum pump: 1, Primary shut-off valve 2, Secondary shut-off valve 3, Air safety filter, 4, Vacuum relief valve 5, Pressure relief valve 6, Vacuum pressure gauge 7, Silencer (Oil catch muffler) |

|||

|

12) Suction hose |

Material |

PVC along with quick connect coupling |

||

|

Type and size |

Non-collapsible flexible |

|||

|

Hose Tray |

2 hose trays each one on the left and right |

|||

|

13) Color |

To be confirmed during the contract agreement. |

|||

|

14) Instrumentation |

Temperature Gauge |

Manufacturer standard Provided |

||

|

Pressure Gauge |

Manufacturer standard Provided |

|||

|

Level Control |

Manufacturer standard Provided |

|||

|

15) Water tank |

Material |

plastic with soap dispenser |

||

|

Purpose/Application |

for hand cleaning |

|||