Make & Model: CSCTRUCK/SS12ZZ400R2.

Drive Type: 6×4 Right Hand Drive.

Max. Gross Vehicle Weight: 25,000kg.

Wheelbase: 3,625+1,350mm.

Chassis Designed: SINOTRUK HOWO.

Drive wheel(Tires): 6+4 and one spare (total 11 wheels)

Engine Make/Model: WEICHAI / WP12.400E201.

Fuel: Diesel.

|

|

|

|

Description

BRIEF

The SINOTRUK street sweeper truck is a specialized vehicle engineered to efficiently clean and sweep various urban areas, including city roads, highways, construction sites, bridges, squares, and cement concrete road surfaces. Designed for SINOTRUK HOWO chassis, this truck features a truck-mounted superstructure of a vacuum road sweeper with a generous 7 cubic meter waste tank capacity and a 5000-liter water tank.

The sweeper body kit comprises top-of-the-line, wear-resistant stainless-steel tanks, an auxiliary engine, an air blower, a sweeping system, a suction system, a water sprinkling system, a hydraulic system, and an electric system. The truck is equipped with a front spraying bar and hose reel, allowing for effective dust suppression along roadsides and narrow lanes. Additionally, it facilitates the cleaning of the sweeper’s body through a washing function.

Controlling the operations of the street sweeper is convenient and straightforward. The control panel is strategically placed on the right side of the driver’s cabin, providing easy access and clear instructions for the operator. This ensures efficient management and coordination of the various systems and components of the vehicle during sweeping operations.

The SINOTRUK street sweeper truck is a versatile and reliable solution for maintaining cleanliness and tidiness in urban environments. Its powerful vacuum system, coupled with the sizable waste and water tanks, allows for extended periods of operation without frequent emptying or refilling. With its durable construction and high-quality components, this truck is built to withstand the rigors of heavy-duty sweeping tasks, ensuring longevity and optimal performance.

Whether it’s removing debris, dust suppression, or washing the sweeper body, the SINOTRUK street sweeper truck offers a comprehensive and integrated solution for effective road cleaning. Its advanced features and user-friendly design make it an invaluable asset in maintaining the cleanliness and appearance of streets, highways, and construction sites.

FEATURES

1. Efficient Cleaning Capacity: The SINOTRUK street sweeper 12m³ is equipped with a high-capacity cleaning system that can clean streets and roads effectively. With a large 12 cubic meter hopper, it has ample space to collect debris, dirt, and litter, minimizing the need for frequent unloading.

2. Advanced Cleaning Technology: This street sweeper incorporates advanced cleaning technology to ensure thorough and efficient cleaning. It utilizes a combination of sweeping brushes, suction, and water spraying systems to remove different types of debris, including dust, leaves, stones, and larger objects.

3. Easy Maneuverability: The SINOTRUK street sweeper is designed for ease of use and maneuverability. It features a compact and agile design, allowing it to navigate through narrow streets, crowded areas, and tight corners. This enables efficient cleaning in urban environments where larger vehicles may struggle to access.

4. Environmental Friendliness: As an environmentally conscious solution, the SINOTRUK street sweeper incorporates features to minimize its impact on the environment. It utilizes water recycling systems to reduce water consumption during the cleaning process, helping to conserve this valuable resource. Additionally, it is equipped with an efficient dust suppression system to prevent dust particles from being released into the air.

5. User-Friendly Operation: The street sweeper is designed with the operator in mind, offering a user-friendly interface and intuitive controls. The cabin provides a comfortable working environment with adjustable seating and excellent visibility. The controls are ergonomically positioned, making it easy for the operator to navigate and control the sweeping operations efficiently. Additionally, the sweeper is equipped with various safety features to ensure the well-being of the operator and pedestrians.

SPECIFICATION

|

PARTS |

ITEM |

DESCRIPTION |

|

General Information

|

1.1 Make & Model |

CSCTRUCK / SS12ZZ400R2 |

|

1.2 Date of Manufacturing |

2023 |

|

|

1.3 Country of Origin |

China |

|

|

1.4 Truck Unit’s Status |

Brand new |

|

|

1.5 CSCTRUCK’s Status |

Established and reputable |

|

|

1.6 Drive Type |

6×4 Right Hand Drive |

|

|

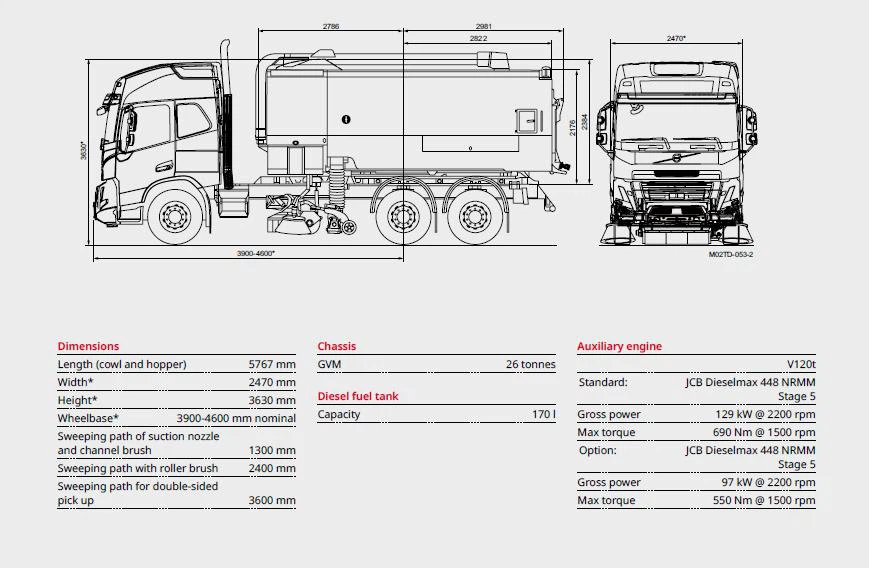

1.7Overall Dimension (L x W x H) |

8,748*2,500*3,280mm |

|

|

1.8 Max. Gross Vehicle Weight |

25,000kg |

|

|

1.9 Curb Weight |

14,480kg |

|

|

1.10 F/R Axle-Load |

9/16Tx2 |

|

|

1.11 Wheelbase |

3,625+1,350mm |

|

|

1.12 Air Over Hydraulic System |

The chassis’ system is air-over hydraulic |

|

|

1.13 Rear Tow/Pintail Hook |

Installed |

|

|

1.14 Standard Tool Kit |

Supplied |

|

|

1.15 Mud Flaps |

Installed |

|

|

1.16 Chassis Designed |

SINOTRUK HOWO |

|

|

1.17 Cabin |

Hydraulic power steering type. 1 driver+2 passengers |

|

|

1.18 Drive wheel(Tires ): |

6+4 and one spares (total of 11 wheels) |

|

|

1.19 Capacity: |

12M3 (7m³ garbage tank+5,000L water tank) |

|

|

Engine

|

2.1 Make / Model |

WEICHAI / WP12.400E201 |

|

2.2 Country of Origin |

China |

|

|

2.4 Type |

6 cylinders in line, 4 strokes direct injection, water cooling, Intercooler Turbocharged |

|

|

2.5 Air Intake |

Turbo-charged |

|

|

2.6 Fuel |

Diesel |

|

|

2.7 Cooling System |

Water cooling system |

|

|

2.8 Displacement |

11.596L |

|

|

2.9 Nominal Power |

400HP (294kW) @ 1,900rpm |

|

|

2.10 Peak Torque |

1,800N.m@1,000~1,400rpm |

|

|

2.11 Emission Standard |

Euro 2 |

|

|

2.12 Max. Rotated Speed |

1,000~1,400rpm |

|

|

2.13 Bore x Stroke |

Φ126×155mm |

|

|

2.14 Used |

The engine is used to power the remaining system through a hydrostatic drive and all components through a hydrostatic drive. |

|

|

2.15 Electronics |

The engine electronics accept a remote variable throttle for stationary operation through transmission-mounted PTO and transfer case-driven PTO equipment. The air cleaner is to be the manufacturer’s recommended dual air. Air restriction gauge, dash-mounted or approved equal. |

|

|

2.16 Included |

Turbo, injectors, starter, and alternator. Automatic engine shutdown system with low oil pressure, high coolant temperature, and low coolant level. |

|

|

3) Clutch and Transmission

|

3.1 Operation of Transmission |

Manual with synchromesh |

|

3.2 Hydraulic, Clutch Actuation |

Hydraulic operating with air assistance |

|

|

3.3 Clutch Type |

SINOTRUK Φ430 diaphragm-spring clutch, hydraulically operating with air assistance |

|

|

3.4 Number of Speeds of Transmission |

10F+2R Ratio:14.28, 10.62, 7.87, 5.88, 4.38, 3.27, 2.43, 1.80, 1.34, 1.00, 13.91(R1), 3.18(R2) |

|

|

3.6 Fuel Type of Transmission |

Diesel |

|

|

3.7 Model/Make of Transmission |

SINOTRUK/HW19710 |

|

|

3.8 Fuel type |

Diesel |

|

|

4) Brakes and Tyres

|

4.1 Brakes |

Hydraulic-pneumatic assisted, dual circuit, pressure-air, air dryer. |

|

4.2 Brake Type |

Drum brake with ABS |

|

|

4.3 Tire Size |

12.00R20 |

|

|

4.4 Total Number of Wheels with Spare |

10 wheels and 1spare |

|

|

4.5 Service Brake |

Dual circuit pressure-air brake acting on wheels of all axles. |

|

|

4.6 Emergency Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.7 Parking Brake |

Spring type, acting on wheels of rear axles. |

|

|

4.8 Auxiliary Brake |

Engine brake, flap type exhaust brake. |

|

|

5) Suspension

|

5.1 Front Type |

Heavy-duty leaf springs with telescopic shock absorbers at the front |

|

5.2 Rear Type |

Heavy-duty leaf springs |

|

|

6) Cab

|

6.1 Type |

4-point full-floating air suspension, with 1 sleeper |

|

6.2 Installed |

Air-conditioned, audio system |

|

|

6.3 Passengers Allowed |

2+1 persons |

|

|

6.4 Color |

Based on requirement |

|

|

6.5 Top |

Orange rotating beacon light on top |

|

|

6.6 Safety Belts |

Installed |

|

|

7) Axles

|

7.1 Loading Capacity of Front |

HF9, 9T Steering with a double T-cross section beam |

|

7.2 Loading Capacity of Rear |

HC16, 16Tx2 Pressed axle housing, central single reduction with hub reduction, with differential locks between wheels and axles. |

|

|

8) Electrical System on Chassis

|

8.1 Working Voltage |

24V, negative grounded |

|

8.2 Starter |

24V, 5.4kw |

|

|

8.3 Alternator |

3-phase, 28V |

|

|

8.4 Battery Type |

2 x 12V -165A.H |

|

|

9) Tank

|

9.1 Composite |

Water Tank and Garbage Tank |

|

9.2 Capacity |

12 m3 (7m³ garbage tank+5,000L water tank) |

|

|

9.3 Material |

304 stainless steel |

|

|

9.4 Dumping By |

A telescopic cylinder lifts the garbage tank |

|

|

9.5 Dumping Angle |

≥55° |

|

|

10) Auxiliary Engine

|

10.1 Make/Model |

JCB Dieselmax 448 NRMM Stage 5 |

|

10.2 Power |

129 kW @ 2200 rpm |

|

|

10.3 Fuel |

Diesel |

|

|

11) Air Blower

|

11.1 Type |

High pressure, centrifugal, sweeping truck-specific used blower |

|

11.2 Sweeping Speed |

1800 rpm – 3500 rpm |

|

|

11.3 Driving Mode |

Drive by the ancillary engine, automatic clutch, V belt powered |

|

|

13) Hydraulic System

|

13.1 Type |

Electro-hydraulic Centralized Control

|

|

13.2 Main Components |

Gear pump, Gerotor motors, Hydraulic cylinders, solenoid valves, IC, manual pump, etc. |

|

|

14) Water Sprinkling System

|

14.1 Main component |

Electric water pump、water filter, nozzle, water tanker, etc. |

|

14.2 Water Spray |

Spray bar in the front, on the side brush, cylinder brush, and suction nozzle. |

|

|

14.3 Wandering Hose |

Located on the rear part of the sweeper, water injection for dust control. |

|

|

15) Electrical System

|

15.1 Con-structure |

Two batteries (in series) |

|

15.2 Voltage |

24V |

|

|

16) Sweeping System

|

16.1 Type |

Brushes installed between front and rear axle, driven by gerotor motor. Left and right brushes are controlled to lift up and down separately. Brushes and suction nozzle are gang controlled for up and down. |

|

16.2 Sweeping Path |

Sweeping path of suction nozzle and channel brush 1300 mm; Sweeping path with roller brush 2400 mm; Sweeping path for double-sided pick up 3600 mm |

|

|

16.3 Sweeping disc speed |

High speed:160r/min |

|

|

16.4 Sweeping disc tilt angle |

Front tilt 4°~6°; right and left tilt 2°~4° 6°~10° |

|

|

17) Suction System

|

17.1 Type |

U-shaped servo Suction nozzle |

|

17.2 Suction hose diameters |

Φ250mm |

|

|

18) Suction System

|

18.1 Control Panel |

All control functions of the sweeper are done inside the cabin |

|

18.2 Auxiliary Control |

ON/OFF Switch |

|

|

19) Others |

19.1 Components |

Backup camera; Dust hopper self-cleaning hose and nozzle; Front Spray Bar; Rear LED Lamp |

|

20) Painting

|

20.1 Both Painted |

The exterior and interior of the tank are spray painted with high-quality painting |

|

20.2 Exterior |

Spray-painted with two coats of superior quality anti-corrosive primer and two coats of enamel metal paint of a reputed make. |

|

|

20.3 Under Chassis |

Coated with anti-corrosion. |